In modern logistics, warehousing, and industrial loading scenarios, Dock Lifts and Dock Levelers are two commonly used equipment types for bridging the height gap between trucks and loading areas. Although they serve similar purposes, they differ significantly in structure, function, and applicable use cases.

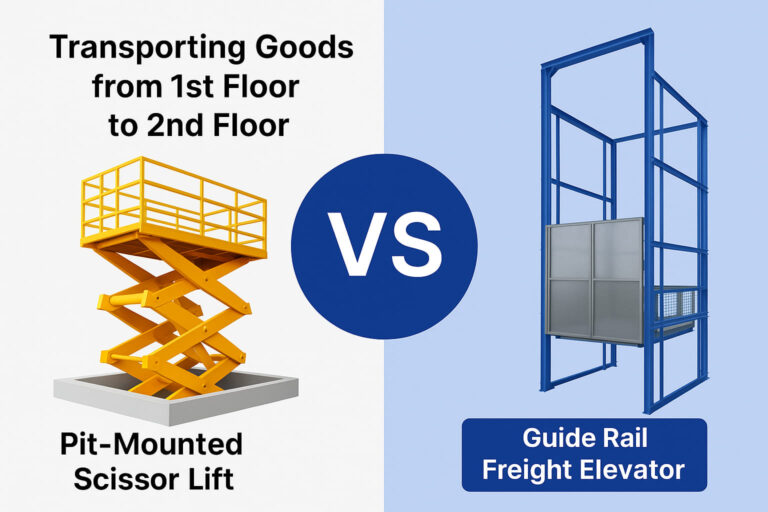

1、What is a Dock Lift?

A Dock Lift is a hydraulically powered lifting platform that can raise goods from ground level to truck bed height or lower goods from trucks to the ground. It is often installed in a pit, with the platform flush with the floor, and does not require a fixed dock. Due to its ability to move vertically, a dock lift is especially suitable for facilities without a loading dock or those that need to accommodate trucks of varying heights.

Key Features:

Can be used independently; highly flexible

Supports scissor lift structure; strong load capacity

Adjustable lifting height; compatible with various vehicle types

Suitable for forklift or pallet jack loading and unloading

Scissor Lift Cases:

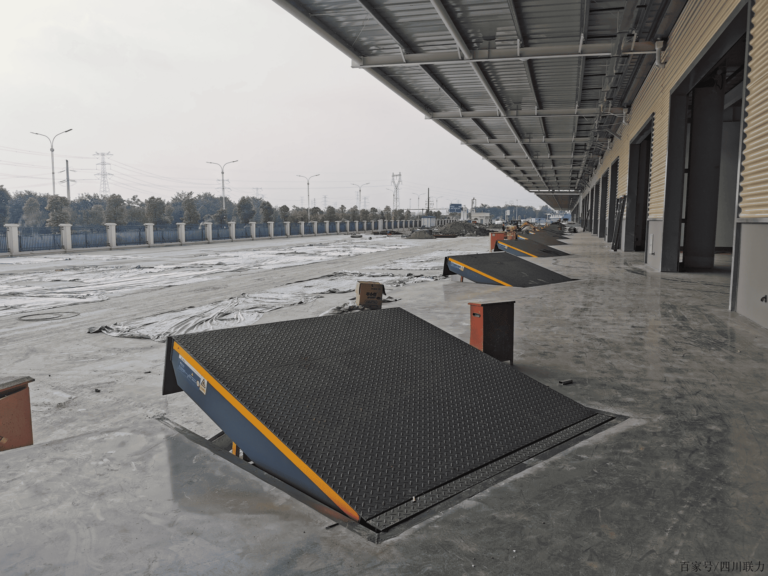

2、What is a Dock Leveler?

A Dock Leveler is an adjustment device installed at the edge of a fixed loading dock. It uses a hinged metal plate (lip) to bridge the gap between the dock and the truck. Dock levelers cannot move vertically; they only offer limited height adjustment and are suitable for standardized operations where truck bed heights are relatively consistent.

Key Features:

Must be used with a fixed dock

Simple structure, low cost

Limited adjustment range (typically ±300mm)

Ideal for frequent, high-efficiency loading operations

Dock Levelers Case:

3、Dock Lift vs. Dock Leveler: Comparison Overview

Usage Method: Dock Lifts are self-sufficient; Dock Levelers rely on a fixed dock

Height Adjustment: Dock Lifts offer wide lifting range; Dock Levelers offer limited range

Application Scenarios: Dock Lifts suit ground-level loading and various truck heights; Dock Levelers suit standard docks and consistent vehicles

Cost: Dock Lifts are higher cost; Dock Levelers are more economical

Customization: Dock Lifts are highly customizable; Dock Levelers are often standard models

| Item | Dock Lift | Dock Leveler |

|---|---|---|

| Structure | Hydraulic lift platform (scissor type / guide rail type) | Fixed flip-lip structure, mounted on dock edge |

| Independent Operation | Yes, no dock required | No, requires fixed loading dock |

| Height Adjustment | Wide range, fits various truck heights | Limited, typically ±300mm |

| Load Capacity | Strong, supports 2–10+ tons (customizable) | Medium, typically 6–10 tons |

| Installation | Pit-mounted or ground-placed | Embedded at dock edge |

| Typical Applications | No-dock factories, forklift loading, varied truck heights | Standard docks, frequent loading, consistent truck sizes |

| Advantages | Flexible, wide height range, high safety, works standalone | Simple structure, low cost, easy to maintain |

| Disadvantages | Higher cost, more complex installation, requires space | Limited use conditions, small adjustment range |

4、How to Choose?

If your site does not have a fixed dock, a Dock Lift is recommended due to its flexibility and ability to handle different trucks.

If you already have a standard loading dock and truck heights are mostly uniform, a Dock Leveler is a more cost-effective solution.

If you require forklift access, heavy load capacity, or greater height variation, a Dock Lift is the safer and more versatile option.

For high-frequency, fast-paced operations, Dock Levelers are ideal for standardized workflows.

Conclusion

Dock Levelers are best suited for standardized, high-frequency dock environments with lower investment and simpler installation. In contrast, Dock Lifts are ideal for ground-level loading, diverse vehicle types, or applications requiring forklift access and greater height flexibility.

Still not sure which one fits your operation? We offer customized Dock Lifts and Dock Levelers in various sizes and specifications. Contact us for tailored loading solutions.