Custom Heavy Duty Scissor Lift Table – Truck loading & vertical transfer

Built for Heavy Loads, Designed for Precision

Heavy Duty Scissor Lift Introduction

Our heavy-duty scissor lifts come in both pit-mounted and pit-free designs to suit different installation needs. They are widely used for ground-to-truck loading, mezzanine access, and heavy equipment handling in warehouses, factories, and logistics centers. Whether installed flush with the floor or placed on a reinforced base, these lifts provide stable, safe, and efficient lifting for heavy loads.

This heavy-duty scissor lift platform is built to raise large equipment—such as HDD rigs—from ground level to truck bed height, making loading safer, faster, and more efficient.

More than just lifting, this scissor lift also serves as a stable work platform for aligning and transferring heavy steel tubes between ground level and processing stations.

This lift enables vertical movement of vehicles between floors in garages or showrooms, helping cars move from ground level to upper levels without ramps or car elevators.

Designed for smooth truck loading, this platform bridges height gaps between the ground and truck bed, allowing forklifts or workers to load goods like pallets and machinery easily.

This heavy-duty fixed scissor lift platform is ideal for unloading long items such as steel pipes or aluminum tubes from trucks. It adjusts to match the height of the truck bed or warehouse floor, improving both safety and handling efficiency.

This underground car lift platform is designed to lower vehicles like cars or trucks into a hidden pit, keeping the surface flat and walkable. It’s perfect for garages, commercial buildings, and residential spaces with limited surface space.

This heavy-duty scissor lift platform bridges the height gap between the ground and truck bed, making loading fast and secure. It ensures smooth operations for forklifts or workers moving pallets, equipment, or other heavy goods.

This circular scissor lift platform is built for performance venues and stage setups, offering stable lifting of props, actors, or equipment. It ensures smooth elevation during use, with safety markings for enhanced security on stage.

Advantages of Our Heavy Duty Scissor Lift Platforms

Our heavy-duty scissor lift platforms are designed for industrial-grade performance. With reinforced scissor structures, high-capacity hydraulic cylinders, and customizable sizes, they ensure stable lifting, high load capacity, and long-term reliability for your toughest jobs.

Reinforced Scissor Arms

The heavy-duty scissor arms are made from thick steel profiles, providing exceptional strength and structural stability during vertical lifting. Precision welding and robust joints ensure long-lasting performance under high loads.

Chrome-Plated Hydraulic Cylinder

This industrial-grade hydraulic cylinder features a chrome-plated piston for superior corrosion resistance and smooth operation. It delivers powerful and stable lifting performance, even in continuous-duty applications.

Underside Support Structure

The underside of the platform is reinforced with crossbeams and structural ribs, increasing overall rigidity and preventing flexing under heavy loads. This design ensures platform stability and safety during operation.

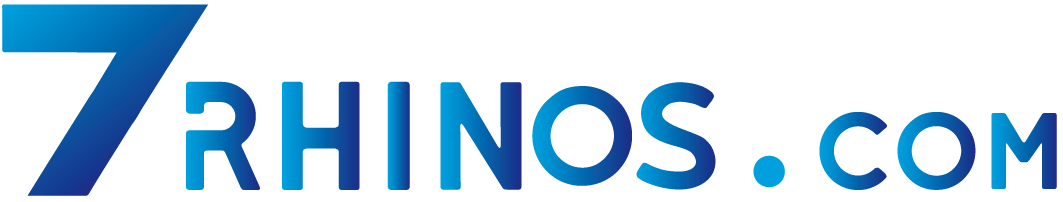

Industrial Power Unit

Equipped with a high-efficiency motor and integrated hydraulic pump, this power unit delivers strong and reliable lifting force. All wiring is securely arranged for safe and stable operation in demanding environments.

Heavy-Duty Support Base

Built from premium Q235 thick steel with precision welding, this reinforced base ensures maximum load stability and long-term durability even under heavy industrial conditions.

Industrial-Grade Hydraulic Power Unit

Built with a high-performance motor and precision pump, this power unit ensures efficient oil flow, stable pressure output, and long-lasting durability. Designed for heavy-duty lifting applications.

Intuitive Up/Down Control Pendant

Featuring a simple and durable pendant controller, operators can lift and lower the platform with ease. Its waterproof housing and ergonomic design enhance both safety and user comfort.

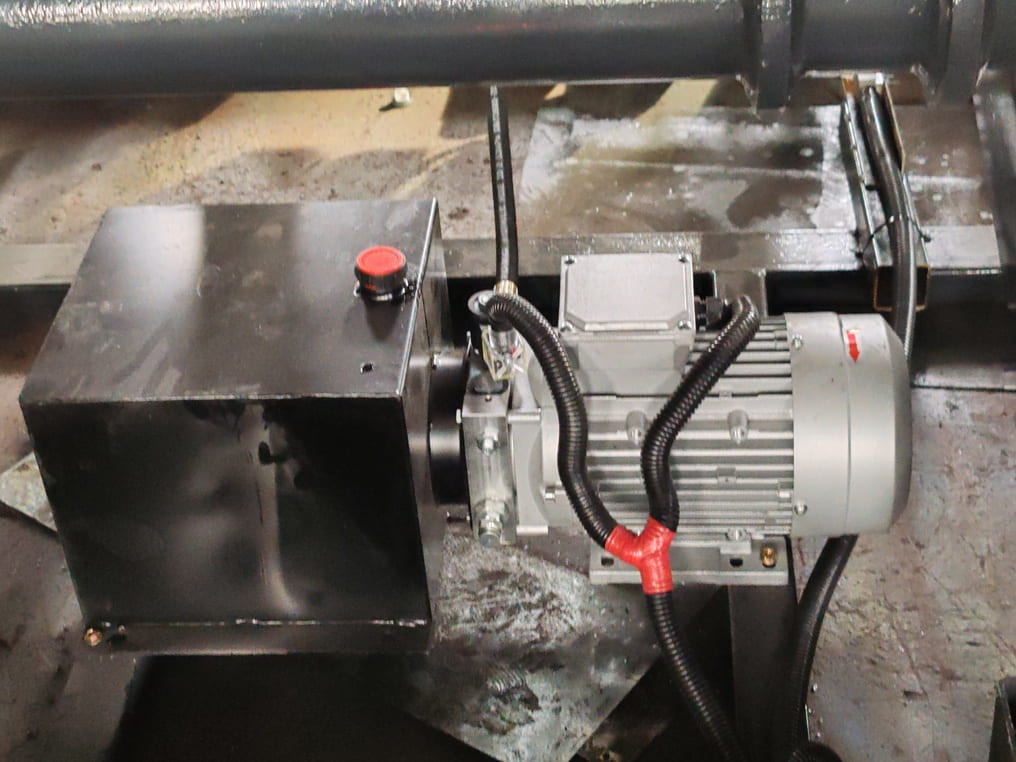

Smart Electrical Control System

The centralized control panel integrates emergency stop, power indicator, and operation switches, enabling precise and safe lift control. Supports customization for remote or foot switch operation.

Heavy Duty Scissor Lift Specifications

Available in both pit and pit-free types, our heavy-duty scissor lifts support custom sizes, strong base frames, and stable lifting performance.

| Model | Rated Capacity (kg) | Platform Size (mm) | Base Frame Size (mm) | Min. Height (mm) | Max. Height (mm) | Lift Time (s) | Power Pack | Net Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 7R6001 | 6000 | 1700×1000 | 1600×990 | 385 | 1145 | 25-35 | 380V/50Hz, AC2.2kw | 475 |

| 7R6002 | 6000 | 1700×1200 | 1600×990 | 385 | 1145 | 25-35 | 380V/50Hz, AC2.2kw | 495 |

| 7R6003 | 6000 | 1800×1000 | 1600×1000 | 390 | 1150 | 25-35 | 380V/50Hz, AC2.2kw | 555 |

| 7R6004 | 6000 | 1800×1200 | 1650×1000 | 390 | 1150 | 25-35 | 380V/50Hz, AC2.2kw | 586 |

| 7R6005 | 6000 | 1600×1400 | 1560×1000 | 390 | 1150 | 25-35 | 380V/50Hz, AC2.2kw | 618 |

| 7R6006 | 6000 | 1600×1300 | 1560×1000 | 390 | 1150 | 25-35 | 380V/50Hz, AC2.2kw | 670 |

| 7R6007 | 6000 | 1600×1500 | 1600×1000 | 390 | 1150 | 25-35 | 380V/50Hz, AC2.2kw | 698 |

| 7R6008 | 6000 | 1800×1500 | 1600×1000 | 390 | 1150 | 25-35 | 380V/50Hz, AC2.2kw | 742 |

| 7R6009 | 6000 | 2000×1800 | 1600×1000 | 390 | 1150 | 30-40 | 380V/50Hz, AC2.2kw | 788 |

| 7R60010 | 6000 | 2000×2000 | 1600×1000 | 400 | 1150 | 30-40 | 380V/50Hz, AC2.2kw | 818 |

| 7R60011 | 6000 | 2000×1400 | 1955×1000 | 400 | 1600 | 30-40 | 380V/50Hz, AC2.2kw | 728 |

| 7R60012 | 6000 | 2000×1400 | 1955×1000 | 400 | 1600 | 30-40 | 380V/50Hz, AC2.2kw | 728 |

| 7R60013 | 6000 | 2200×1400 | 1955×1000 | 400 | 1600 | 30-40 | 380V/50Hz, AC2.2kw | 765 |

Scissor Type Goods Lift

Scissor Type Goods Lift is a heavy-duty hydraulic platform designed to transfer goods vertically between different floors in warehouses, mezzanines, or production areas. With a stable scissor structure and customizable platform size, it provides a safe, efficient, and cost-effective solution for daily material handling. Ideal for logistics centers, e-commerce warehouses, and industrial storage spaces.

With a scissor-type goods lift, cargo can be easily transported from the first floor to the second or third floor, improving loading efficiency and reducing manual handling costs. The platform operates smoothly and is ideal for multi-level warehouses, mezzanine floors, and sorting centers.

Designed for warehouse use, this hydraulic scissor lift platform offers a reliable solution for moving goods between multiple floors. It requires no shaft construction, has low installation cost, and is built to handle heavy loads with ease. Safety rails and mesh guards ensure secure operation during lifting.

Our scissor-type goods lifts are engineered for demanding warehouse environments, supporting up to 6 tons of cargo. The system features precision hydraulic control, industrial-grade steel arms, and customizable safety configurations. A perfect choice for multi-level storage and distribution centers.

Heavy Duty Scissor Lift Customer Case

We have successfully installed heavy duty scissor lift platforms for clients across various industries and countries. Below are real footage clips taken on-site, showcasing the stability and efficiency of our equipment in real working environments. These cases demonstrate both our product quality and professional installation capability.

This 15-ton scissor lift platform was customized for a client to handle the vertical transfer of excavators, drilling machines, and other heavy equipment. It significantly improves loading efficiency and solves challenges in transporting large machinery.

This is a custom-built 15-ton heavy-duty fixed scissor lift platform designed for transporting large drilling rigs, injection molding machines, and other heavy equipment. It allows for smooth and efficient transfer of machinery onto trucks, making the loading process safer and more convenient.

This project features a custom-built heavy-duty car scissor lift platform with a pit-mounted design, maximizing space utilization while allowing smooth vertical movement of vehicles between levels. The platform is reinforced for high load capacity and includes a fixed upper frame designed for installing a canopy or shelter, effectively protecting the vehicles from rain. It’s ideal for garages, showrooms, villas, and other premium-use scenarios.

This project features a custom-built heavy-duty fixed scissor lift, designed for a car dealership to transport vehicles from the ground floor to the second-floor warehouse. The lift is highly stable and capable of supporting full vehicle loads, greatly improving storage efficiency. With a pit-style installation, it maximizes usable space and provides a reliable solution for automotive storage, repair, and showroom applications.

This custom-built heavy duty scissor lift was designed to transport goods from the ground floor to a second-floor warehouse. Built for stability and strength, it offers a highly efficient solution for industrial cargo handling and warehouse logistics. Compared to traditional forklift operations, it significantly reduces labor time and improves overall work efficiency.

This custom-built heavy duty scissor lift platform is designed to assist with truck loading operations. It lifts goods from the ground to align with the truck bed, making it easy to move cargo directly into the vehicle. The system greatly improves loading efficiency and reduces handling time and labor, making it ideal for warehouses, logistics centers, and distribution hubs.

Heavy Duty Scissor Lift Blog

We share the latest technologies, product updates, and company news about Heavy Duty Scissor Lifts. Browse our curated blog posts to learn how to optimize equipment usage, improve work efficiency, and stay up-to-date with industry trends.

Add a short headline

Request a Quote for Our Heavy Duty Scissor Lifts

Let us know your requirements for a heavy duty scissor lift. Our custom-built lifts are designed to meet the highest standards of performance and safety. Fill out the form, and our team will get back to you with a tailored quote.